Profile swelling bentonite AQUASTOP PNB

Home / Swelling profile AQUASTOP / PNB

Applications Swelling rubber profiles are used in the following situations:

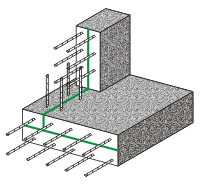

- Sealing technological joints during concrete work, such as “floor-wall,” “wall-wall,” and “wall-slab” connections, except deformation and shrinkage joints subject to movement.

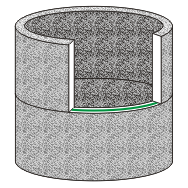

- Sealing joints of precast reinforced concrete structures.

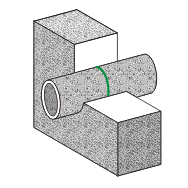

- Sealing utility inputs to buildings and structures.

- Sealing cracks in building structures.

Advantages

- Ease of installation.

- Reliable sealing and tightness of joints due to volume expansion upon contact with water and the creation of a clogging cloud within the structure.

- High durability and frost resistance.

- Maintains its properties through multiple cycles of volume expansion.

- Environmentally safe.

- Chemically resistant.

Packaging |

Quantity |

|---|---|

|

Roll |

5 m. |

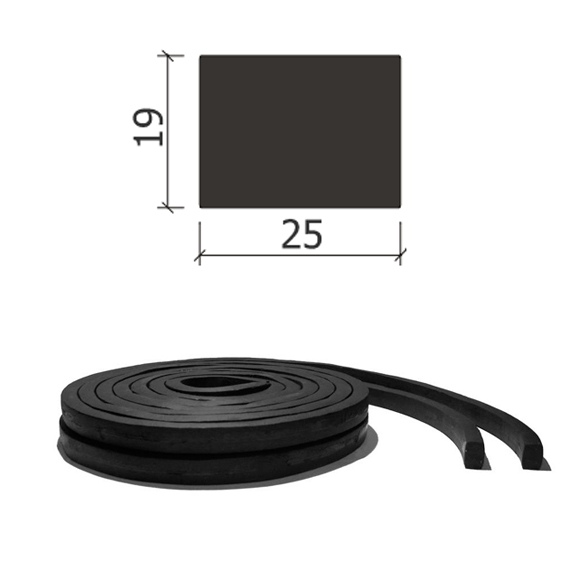

Bentonite Swelling Profile PNB 25x19

Bentonite cord AQUASTOP PNB 25×19 is an insulation and sealing hydraulic gasket.

- Material – Butyl rubber and sodium bentonite;

- Profile Cross-section – Rectangular;

- Dimensions – 25×19 mm;

- Material Density – 1.35 g/cm³;

Installation Temperature Range – from -15 to +50 degrees Celsius;

Distance to edges during installation – at least 75 mm. The composition includes butyl rubber and sodium bentonite. When in contact with water, bentonite absorbs it and significantly increases in volume. The resultant mass is limited only by the concrete walls. The swollen cord resembles a dense waterproof gel.

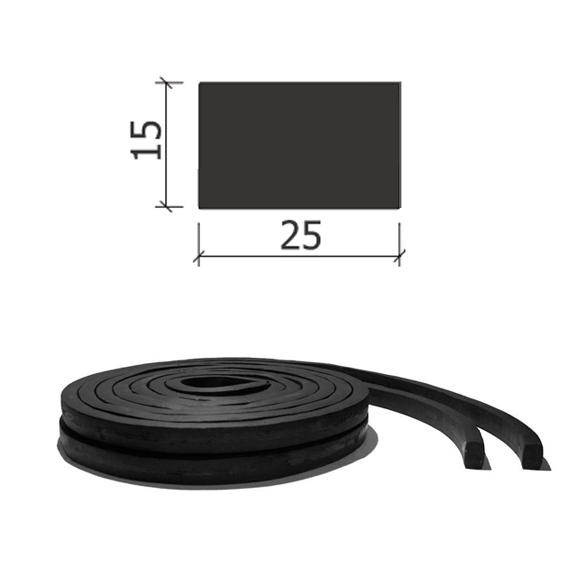

Bentonite Swelling Profile PNB 25х15

- Material – Butyl rubber and sodium bentonite;

- Profile Cross-section – Rectangular;

- Dimensions – 25×15 mm;

- Material Density – 1.35 g/cm³;

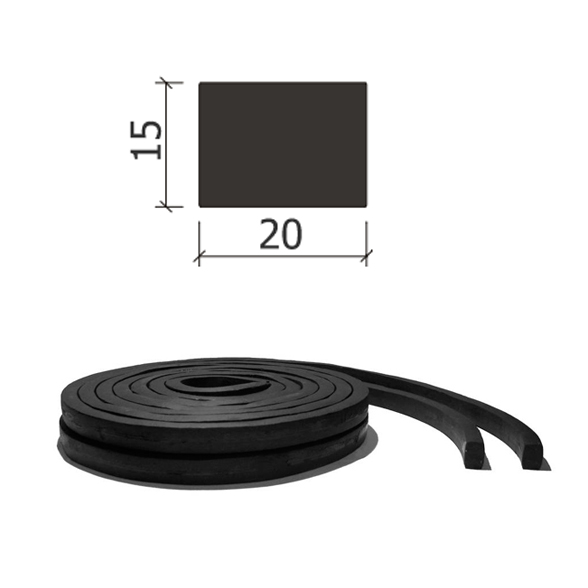

Bentonite Swelling Profile PNB 20х15

Bentonite cord AQUASTOP PNB 20×15 is an insulation and sealing hydraulic gasket.

- Material – Butyl rubber and sodium bentonite;

- Profile Cross-section – Rectangular;

- Dimensions – 20×15 mm;

- Material Density – 1.35 g/cm³;

- Installation Temperature Range – from -15 to +50 degrees Celsius;

Distance to edges during installation – at least 75 mm. The composition includes butyl rubber and sodium bentonite. When in contact with water, bentonite absorbs it and significantly increases in volume. The resultant mass is limited only by the concrete walls. The swollen cord resembles a dense waterproof gel.

Bentonite Swelling Profile PNB 20х10

- Material – Butyl rubber and sodium bentonite;

- Profile Cross-section – Rectangular;

- Dimensions – 20×10 mm;

- Material Density – 1.35 g/cm³;

- Installation Temperature Range – from -15 to +50 degrees Celsius;

Distance to edges during installation – at least 75 mm. The composition includes butyl rubber and sodium bentonite. When in contact with water, bentonite absorbs it and significantly increases in volume. The resultant mass is limited only by the concrete walls. The swollen cord resembles a dense waterproof gel.

- Installation is carried out immediately prior to concrete pouring;

- The concrete surface must be clean, and standing water must be removed.

- Before installation, the anti-adhesive paper must be removed from the profile.

- The PNB profile should be installed in the central part of the structure. The distance to any side of the concrete structure should not be less than 70 mm;

- The cords are joined end to end;

- The profile is placed tightly on the concrete surface of the joint or wrapped around various communication pipes tightly, without gaps, and secured against potential shifting using a special metal mesh fixed with anchors every 150-200 mm.

- During installation, long-term contact with atmospheric water should be avoided. If such a situation occurs, the PNB profile must be wiped dry, protected from further moisture, and conditions should be created to facilitate its later drying.

Download Files for AQUASTOP Waterstop Sealing Profiles

Development of a waterproofing plan for your project

Our design team, after promptly reviewing the project’s technical documentation, will develop a waterproofing plan that includes all the necessary sections.

Installation Supervision

A specialist visits the construction site to ensure high-quality waterproofing installation.

Design

Our design team will promptly review the technical documentation and develop a comprehensive waterproofing plan that includes all required sections.

Consulting

Choosing materials for building and structure waterproofing is a crucial aspect, that ensures the quality and effectiveness of the materials we work with.